2025-08-26

Thickness

The thickness of aluminum foil for bottle cap typically ranges from 0.20mm to 0.23mm, with slight variations depending on the application. For example, carbonated beverage caps may require thicker material to withstand the higher internal pressures, while caps for standard beverages or pharmaceuticals are relatively thin.

The thickness selection must be carefully considered, along with the bottle cap's strength requirements, cost, and processing feasibility. If the thickness is too thin, the cap may crack easily during processing and may not provide adequate sealing and strength during use. If the thickness is too thick, material costs may increase and forming difficulties may occur during complex processing steps.

Alloys

Common aluminum bottle cap alloys include 8011 and 3003. 8011 alloy offers excellent processing properties and surface quality, with moderate strength, meeting most bottle cap manufacturing requirements. It also performs stably during subsequent stamping and stretching processes, making it less susceptible to cracking and other defects.

3003 alloy, on the other hand, offers excellent corrosion resistance and high strength, making it a more suitable material for products requiring long-term storage or requiring a tight seal, such as alcoholic beverages and pharmaceuticals. The choice of alloy depends on the intended use and performance requirements.

Strength: Bottle caps must possess sufficient strength to prevent deformation or damage during packaging, transportation, and use. For example, during the high-speed packaging process on the production line, bottle caps are subject to certain mechanical stresses.

Sealing: This is a crucial performance characteristic of aluminum bottle caps. Achieving a good seal requires not only the right material but also precise control of the aluminum sheet's dimensional accuracy and surface flatness during processing, as well as subsequent sealing.

Processability: The selected aluminum sheets should be easy to process through operations such as stamping, stretching, trimming, and hemming. Good processability improves production efficiency, reduces scrap rates, and facilitates the high-precision manufacturing of complex bottle cap designs.

Surface Quality: The surface must be flat, free of rolling marks, scratches, and stains, ensuring clear and aesthetically pleasing patterns and logos during subsequent printing or painting.

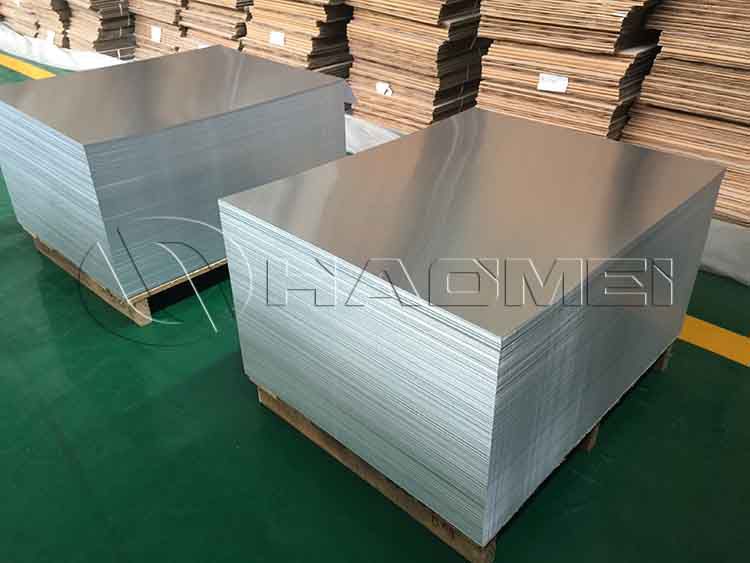

Cutting

Aluminum coils are cut to specific dimensions, producing aluminum sheets suitable for stamping. Our cutting equipment typically utilizes high-precision CNC systems, enabling precise control of the length and width of the cuts, ensuring consistent sheet dimensions.

Cleaning and Passivation

After cutting, aluminum sheets need to be cleaned to remove surface impurities such as oil, dust, and other impurities to ensure the quality of subsequent processing. Passivation forms a dense oxide film on the aluminum sheet surface, enhancing its corrosion resistance and improving the adhesion of subsequent coatings.

Coating or printing

To enhance the aesthetics of aluminum bottle caps and provide protection, the aluminum sheet is coated or printed. The ink or coating used for printing must possess excellent adhesion, weather resistance, and corrosion resistance to ensure that the design will not fade or peel during long-term use. During the printing process, the thickness and uniformity of the 8011a aluminum coating must be strictly controlled to ensure consistent printing quality.

Stamping

Stamping is a key process in aluminum bottle cap manufacturing. A punch press drives a stamping die, stamping the aluminum sheet into a bottle cap blank. The design and manufacturing precision of the stamping die directly impacts the quality and dimensional accuracy of the bottle cap.

Trimming

The edges of the stamped bottle cap blank may be uneven, requiring trimming to ensure dimensional accuracy and aesthetic quality.

The edges of the stamped bottle cap blank may be uneven, requiring trimming to ensure dimensional accuracy and aesthetic quality.

Glue Injection and Drying

To further enhance the sealing performance of bottle caps, sealant needs to be injected into the interior of the caps. The choice of sealant should be determined based on the cap's intended use and product characteristics. For example, for caps used in food packaging, the sealant must meet food hygiene and safety standards. After injection, the caps are dried to cure the sealant and enhance the sealing performance.

Testing

After aluminum bottle caps are manufactured, they undergo comprehensive testing to ensure they meet quality standards. Testing includes dimensional accuracy, sealing performance, and appearance.

Tags: aluminum foil for bottle cap |

Original Source: https://www.alclosuresheet.com/a/how-is-aluminum-cap-manufactured.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com