2025-11-11

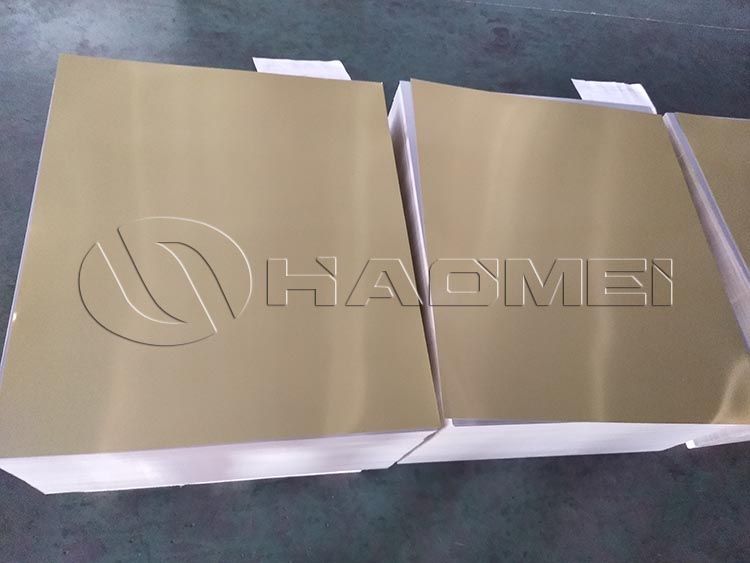

In the packaging industry, bottle caps, as the "guardians" of bottles, must not only possess excellent sealing properties but also be aesthetically pleasing and durable. Aluminum alloy bottle caps, with their numerous advantages, hold a significant position in the market, with 3105 painted aluminum sheet being particularly favored.

Firstly, from a mechanical property perspective, 3105 alloy possesses moderate strength and good ductility. For bottle caps, sufficient strength ensures they are not easily deformed during transportation and use, effectively protecting the product inside the bottle; while good ductility facilitates processing and forming. Whether it's stamping, bending, or stretching, 3105 alloy can easily handle these processes, allowing for the precise manufacture of bottle caps of various shapes and sizes to meet the needs of different bottle packaging.

Secondly, 3105 alloy exhibits excellent corrosion resistance. During use, bottle caps may come into contact with different types of substances such as water, beverages, and cosmetics, some of which are corrosive. 3105 alloy, with its excellent corrosion resistance, effectively resists the erosion of these substances, extending the service life of bottle caps and preventing contamination of the product inside the bottle due to corrosion, thus ensuring product quality and safety.

Furthermore, 3105 alloy has a significant cost advantage. Compared to some high-strength, highly corrosion-resistant special aluminum alloys, 3105 alloy has relatively lower raw material and processing costs. While ensuring bottle cap performance, it effectively reduces production costs for enterprises, enhancing the market competitiveness of products. This is one of the important reasons why many bottle cap manufacturers choose 3105 alloy.

In the food and beverage industry, it is one of the most common bottle cap materials. For example, carbonated beverage bottles, juice bottles, and tea bottles often use 3105 color-coated bottle cap material to make bottle caps. These bottle caps not only effectively seal the bottle opening, preventing beverage leakage and spoilage, but their colorful appearance also attracts consumers' attention and enhances the product's visual appeal.

For beer bottles, 3105 color-coated cap material plays a crucial role. It can withstand a certain amount of pressure, ensuring that the cap won't break due to excessive pressure during storage and transportation. Its excellent sealing properties also guarantee the beer's taste and quality.

In the cosmetics industry, 3105 color-coated cap material also holds a significant place. Many skincare and cosmetic bottles, such as lotion bottles, serum bottles, and cream bottles, choose 3105 color-coated cap material for their caps.

Cosmetics have high requirements for the appearance and texture of their packaging. Through different color-coating processes and designs, 3105 color-coated cap material can create exquisite and high-end appearances that match the positioning of cosmetics and enhance the product's quality. At the same time, its excellent sealing properties effectively protect the active ingredients in cosmetics, preventing their evaporation and external contamination.

In the pharmaceutical industry, some drug packaging bottles also use 3105 color-coated cap material. Pharmaceutical packaging has extremely stringent requirements for safety and stability. 3105 color-coated bottle cap material meets relevant pharmaceutical packaging standards, is non-toxic and odorless, and will not chemically react with pharmaceuticals, ensuring the quality and safety of medicines within their expiration date. Furthermore, its excellent sealing properties prevent moisture and oxidation, guaranteeing the efficacy of the medicine.

The choice of color coating paint is crucial for 3105 color-coated bottle cap material, as it affects not only the appearance of the cap but also its performance and safety. Several factors need to be considered when selecting color coating paint. Haomei Aluminum, one of the aluminum bottle cap material manufacturers, will give you some reference.

First and foremost, safety is paramount. Especially for bottle caps used in food, beverage, cosmetic, and pharmaceutical packaging, the color coating paint must meet relevant safety standards, such as food contact material safety standards, cosmetic packaging safety standards, and pharmaceutical packaging material safety standards.

The paint must not contain substances harmful to the human body, such as heavy metals, formaldehyde, and benzene, to prevent these harmful substances from migrating into the product inside the bottle and posing a health hazard. Therefore, when choosing paint, it's essential to check the paint's test report to ensure that all indicators meet relevant standards.

Secondly, adhesion is a crucial performance characteristic. The paint needs to adhere firmly to the surface of the 3105 alloy bottle cap, preventing peeling, flaking, or paint chipping during transportation, use, and storage. Poor paint adhesion not only affects the appearance of the bottle cap but may also contaminate the product inside.

To ensure paint adhesion, the surface of the 3105 alloy bottle cap requires rigorous pretreatment before color coating, such as degreasing, rust removal, and phosphating, to remove surface oil, impurities, and oxide layers, improving surface roughness and adhesion. Simultaneously, it's crucial to select a paint type and matching primer and topcoat that are compatible with the 3105 alloy surface.

Furthermore, weather resistance and chemical resistance cannot be ignored. During use, the bottle cap may be exposed to various environments, such as sunlight, high temperatures, humidity, and contact with various chemicals.

Therefore, color-coated paints need to possess excellent weather resistance, resisting ultraviolet radiation and preventing fading or discoloration; they also need good chemical resistance, resisting the corrosive effects of water, beverages, cosmetics, and pharmaceuticals, without discoloration, dissolution, or peeling.

When choosing paint, you can select a type with appropriate weather resistance and chemical resistance based on the environment in which the bottle cap will be used and the substances it will come into contact with.

In addition, appearance is also an important factor in choosing color-coated paints. Different products have different requirements for the appearance of bottle caps; some require bright and vibrant colors, some require soft and elegant tones, and some require special gloss or texture effects.

Therefore, when choosing paint, you should consider its color, gloss, smoothness, and other appearance indicators to ensure that it meets the product's design requirements and enhances the product's overall aesthetics and market competitiveness.

Tags: bottle cap material |

Original Source: https://www.alclosuresheet.com/a/3105-aluminum-sheet-for-bottle-caps.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com