2025-05-13

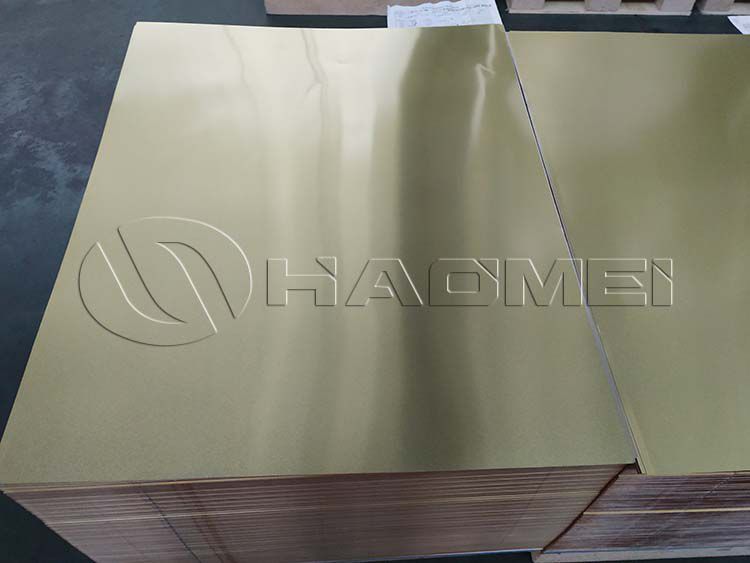

Aluminum bottle cap material is used for making various food and beverage bottle caps. The painted aluminum coils are one of the important types. Its coatings include polyester (PE) coatings and fluorocarbon (PVDF) coatings, which strictly follow food safety standards during production.

Polyester food-grade coating forms a firmly attached continuous solid film by baking the aluminum plate surface multiple times, which has protective and decorative properties. As an anti-UV coating, it uses a high molecular polymer containing ester bonds in the main chain as a monomer, adds alkyd resin and ultraviolet absorber, and is divided into matte and high gloss series according to glossiness.

Fluorocarbon food-grade coating is made of PVDF resin, and its unique fluorine/carbon bond combination makes its physical properties special. In addition to excellent wear resistance and impact resistance in mechanical properties, it has outstanding anti-fading and anti-ultraviolet properties in harsh climates and environments.

Certification standards: Food-grade coatings must be certified by authoritative organizations at home and abroad, such as the U.S. Food and Drug Administration (FDA) certification, China's national standards for food contact materials and products (GB 4806 series), etc. These certifications strictly review the composition, production process and safety of the coating to ensure that it does not migrate harmful substances when in contact with food, protecting the health of consumers.

Safety indicators: There are strict restrictions on the content of heavy metals. For example, the migration of heavy metals such as lead, cadmium, and mercury must be lower than the specified extremely low threshold to prevent heavy metals from contaminating food. At the same time, the content of volatile organic compounds (VOCs) is limited to reduce the volatilization of harmful substances and avoid odor and chemical pollution to food.

Hygiene requirements: During production, storage and transportation, food-grade coatings must maintain high hygiene standards to prevent microbial contamination. The production workshop must meet the clean workshop standards, and the operators must follow strict hygiene regulations to ensure that the coating is not contaminated before use, and to ensure that the final aluminum bottle cap material meets food hygiene requirements.

Chemical resistance: Since the bottle caps will come into contact with various foods and beverages, food-grade coatings must have good chemical resistance and be able to withstand the erosion of acids, alkalis, oils and other substances. During long-term contact with food, the coating will not dissolve, peel off or react chemically, maintaining the integrity of the packaging and the safety of the food.

There are clear standards for coating thickness. The PVDF coating thickness must be ≥25 microns, and the POLYESTER coating thickness must be ≥18 microns. Coating quality also includes other indicators, such as impact resistance requirements of 50kg/cm without paint peeling and cracks; glossiness of 10-90%; coating hardness greater than 2H; adhesion no less than level 1.

These standards ensure that the coating of the color-coated aluminum coil is not easy to fall off or fade in subsequent use, and can maintain a good appearance and protective performance for a long time, while also providing protection for food grade safety.

The common alloys of aluminum bottle caps are 1xxx, 3xxx, and 8xxx series. 1060 aluminum belongs to the 1 series aluminum alloy, which has high purity, good electrical conductivity, thermal conductivity, and corrosion resistance, and good surface treatment performance. It is suitable for ordinary bottle caps with low strength requirements.

3104 and 3105 belong to the 3 series aluminum alloy. Manganese is added to improve strength and corrosion resistance. They have good processing performance, welding performance and coating performance and are widely used in making carbonated beverage bottle caps.

8011 belongs to the 8 series aluminum alloy, which is a deformed aluminum alloy containing lithium and other elements. It has high strength and good processing performance. It is commonly used in anti-theft cover materials.

Bottle caps of different industries and products have different sizes. Aluminum bottle cap materials need to be accurately cut into the coated aluminum sheet metal of specific length, width and thickness according to customer requirements.

Tags: bottle cap material |

Original Source: https://www.alclosuresheet.com/a/painted-aluminum-coils-for-aluminum-seal.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com